Additive Manufacturing

SWARCOFORCE glass filler beads as filling and reinforcing agents in the additive manufacturing of plastics. SWARCOBLAST glass blasting beads are used for post-processing.

Additive manufacturing refers to the construction of parts based on a digital 3D model. The material is added in layers without the use of shaping tools. All shapes can be defined freely within the 3D printer’s build volume. This manufacturing method has proven valuable in prototype construction as well as in the production of both small series and larger lots. Among its advantages, 3D printing allows for a high degree of customization and the production of complex geometries.

Areas of Application

Selective laser sintering (SLS)

Fused deposition modelling (FDM)

Multi jet printing (MJP)

How do SWARCOFORCE glass filler beads enhance the properties of materials?

- Increased scratch resistance

- Improved abrasion resistance

- Optimised rigidity and pressure resistance

- Improved heat resistance

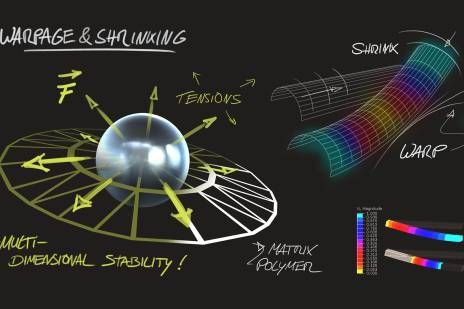

- Reduced warping and shrinking behaviour

- Increased precision of 3D printing results

Glass filler beads improve material properties

SWARCOFORCE glass filler beads from SWARCO Indusferica optimize material properties in the additive manufacturing of plastics. As a filler and reinforcing material, they are used specifically in the selective laser sintering (SLS) and fused depostion modeling (FDM) manufacturing processes. The glass filler beads are added to the powdered polymer or compounded into the filament (FDM) before the printing process. Thanks to the SWARCOFORCE glass filler beads, the finished 3D printed parts exhibit improved shrinkage and warpage behavior as well as optimized mechanical properties, such as stiffness, heat deflection temperature, compressive strength, and scratch and abrasion resistance.

Glass blasting beads for post-processing

Post-processing is another area of application. Especially for 3D printed parts manufactured using SLS, blasting with SWARCOBLAST glass blasting beads is an important post-processing method. This removes the remaining powder and enhances the surface quality.

News and References

Related Products

Contact us

We strive to provide our customers with tailor-made solutions to meet their individual needs.

Andreas Krenmayr

Key Account SWARCOFORCE